For some, doing the hard yards researching stuff is boring. Spending time looking for information that could be better spent actually doing some modeling is just not some peoples idea of a good time. Not me though. I’ve got a real love for researching things I’m interested in, and can in all honesty spend far too much time doing so once I get started.

With the spare room layout, after making the decision to go with the code 55 rail to give it that real branch line look, I’ve been spending some time looking for as many photo’s of branch line track as I can find.

Looking through web sites which contain photo libraries like the New South Wales State Library http://acms.sl.nsw.gov.au can uncover a plethora of absolutely brilliant information. I usually start by using simple word searches to being with like NSWGR, railway, locomotive etc, as these will typically narrow down the subject matter. From there I sometimes find photo collections which mentions the area of the photo which then gives another key to finding more information.

Whilst searching over the past few days I came across the photo of Darnick which I’ve added to this post, and whilst it is a simple photo of a single line running through an almost desolate are with nothing more than a few houses and a gangers shed, the more I looked at it the more it interested me.

Each house is different and is flanked by a different fence, the sleepers are covered in the centre of the track but very little is evident on the outside track edges with the sleepers almost completely exposed, the gangers shed with the sleepers laid out neatly in front of the shed, between the rails and on the far side, 44 gallon drums, the trike, the water tanks, telegraph poles, and even the slight undulation and lay of the land which is not as flat as it first appears with a subtle drainage ditch running alongside the shed and towards the water tanks, and the telegraph poles appearing to have raised ground running either side of them.

For a person with not a lot of space, you could actually spend a lot of time and effort trying to accurately replicate a scene like this as a diorama, or even as a mini scene between two more major features on the layout, and I think it would be as interesting as a multi track main line with stuff crammed in everywhere.

Whilst I can’t see place on my layout for this scene, there are elements within it that could easily be used on almost any layout featuring a branch line feel, and plenty that can be learnt about the way items can be placed around a railway line.

The other area of research I’ve been doing has been in relation to track dimensions especially concerning points with the gauge and flangeway sizes. I’ve looked into the OO-SF standard which closes the gauge up from the std 16.5mm to a narrower 16.2mm, and then setting the flangeways at a narrow 1.0mm giving a much closer to prototype look. But amongst reading lots and lots and lots of information about these dimensions, there was some questions about the effect it may have on the check gauge and I got the feeling that it may not be the most foolproof of dimensions.

Another local modeler of some note, Terry Flynn, has been advocation a set of finer scale dimensions for points which are not too far away from the OO-SF dimensions, but after carefully examining them, appear to be a lot more robust and will suit the mixture of RP25/110 and RP25/88 wheels used on the various bits of rilling stock I own.

Part of the reason for the research onto these dimensions is that I’d like to get some roller gauges made to help with building track and points, and ideally if they are something that others could use, a bigger batch could be ordered cutting costs per unit. At the moment I’ve put some feelers out to get an idea on costs per unit or per batch of units, but it’s a slow process it seems, and I’ll be sure to post up any information I get as it comes to hand.

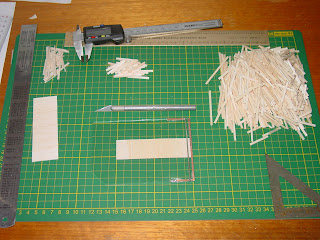

Apart from the research, progress has been slow on actual modeling, and with a relative coming to stay for a week, the spare room has been turned back into a guest room, modeling desk cleaned up enough drop the extension and close the doors to make it all look neat and tidy. Makes it hard to do anything, but that is the compromise I made when subtly trying to turn another area of the house into manland.